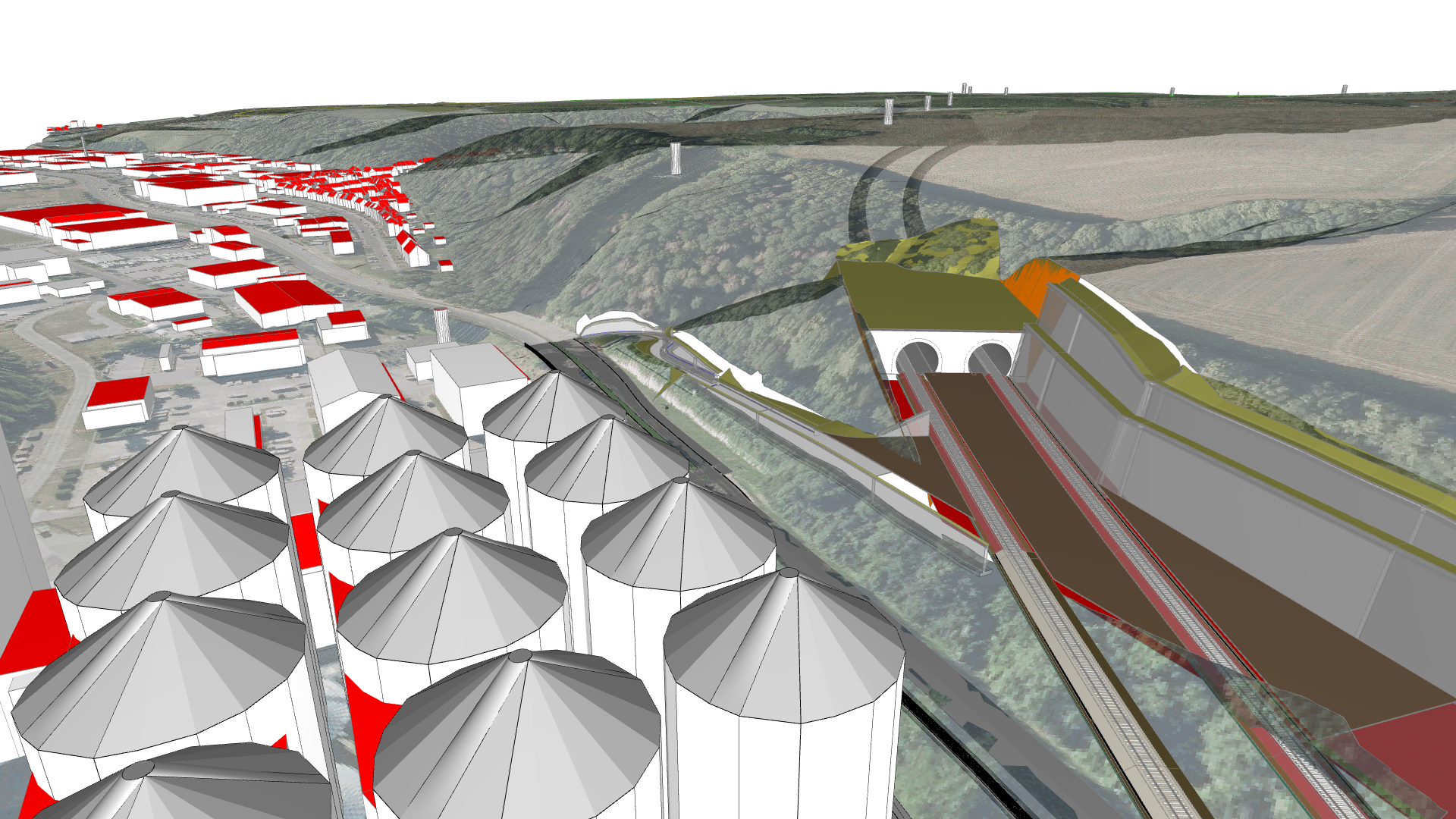

Efficient planning with BIM

Building Information Modelling (BIM) is a working method that uses specialised software to network the various parameters and measurement data collected during the planning phase of a construction project and map them as a three-dimensional model. This model incorporates not only geometric data, but also parameters such as flood values, data from subsoil investigations and equally important factors such as environmental protection and monument conservation. From the very beginning, an important part of this process was the requirement to go through all planning variants with the same care in order to have an optimal basis for further decisions. BIM optimises the entire construction process, from the first planning steps, through all construction phases, to the completion and future maintenance of the project.

The new Dresden – Prague line started in 2019 as a BIM project and thus it will always be prepared to remain a digital, futureproof railroad.